Description

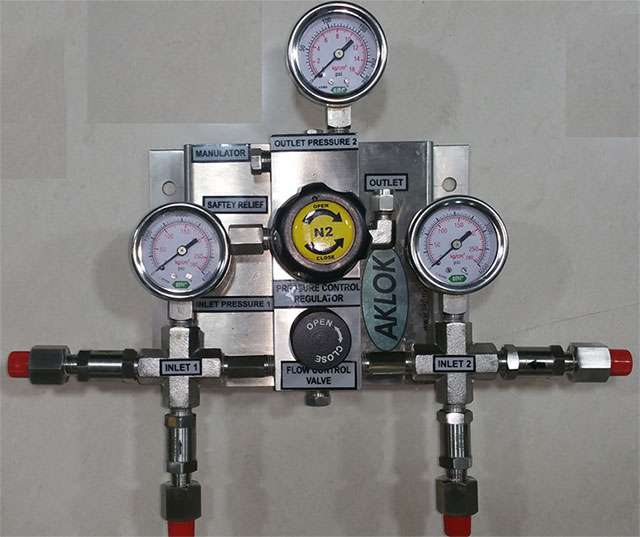

MODEL NO – AKI-01-MN

DESCRIPTION:

ITH INCREASE IN DEMAN FOR MULTIPLE USE OF CYLINDERS, A.K.INDUSTRIES (AKLOK) HAS SUCCESSFULLY DEVELOPED A PRODUCT CALLED MANULATOR. MENULATOR IS DEVELOPED TO REPLACE THE OLD DUAL STAGE AND SINGLE STAGE MANIFOLD SYSTEM WHICHCAN HANDLE ONLY 2 CYLINDERS AT A TIME BUT MANULATOR CAN HANDLE MINIMUM 2 CYLINDER AND MAX 50 CYLINDERS AT A TIME. IT CONTROLS THE PRESSURE OF ALL THE CYLINDER AND DELIVER THE REQUIRED OUTLET PRESSURE FORM 1 SINGLE POINT AT A TIME.

SPECIFICATION:

- MOC – COMPLETE STAINLESS STEEL

- INLET CONNECTION – PIGTAIL CONNECTION (MINIMUM 2 CYLINDER, MAX 4 CYLINDER) (FOR MORE 4 CYLINDERS PIPE MANIFOLD SHOULD BE USED TO CONNECT CYLINDER)

- OUTLET CONNECTION – SWAGELOK TUBE CONNECTION (CAN BE AS PER REQUIREMENT ALSO)

- INLET PRESSURE – 0 TO 280 KG/CM2 MAX

- OUTLET PRESSURE – 0 TO 16 KG/CM2 MAX

- SPECIAL FEATURE – INCLUDES NRV , SAFTEY RELIEF VALVE, IN-BUILT PRESSURE CONTROL REGULATOR, WALL MOUNTING DESIGN, IN-BUILT FLOW CONTROL VALVE

WORKING:

AFTER SUCCESSFUL INSTALLING MANULATOR, CONNECT CYLINDER NO 1 AT INLET 1 WITH PIGTAIL AND CYLINDER NO 2 AT INLET 2 PIGTAIL. MAKE SURE THAT THE FLOW CONTROL VALVE IS OFF DURING INSTALLING CYLINDERS. TURN ON BOTH THE CYLINDER. TURN ON THE FLOW CONTROL VALVE YOU CAN SEE THE INCOMING PRESSURE AT INLET PRESSURE. NOW JUST REGULATE THE REQUIRED PRESSURE REQUIRED IN THE LINE BY USING PRRSSURE CONTROL REGULATOR YOU CAN SEE THE OUT GOING PRESSURE AT OUTLET PRESSURE

IMPORTANT NOTE:

- PLEASE REFFER TO USER MANUAL BEFORE OPERATING

- ALL ABOVE CONNECTIONS AND SETTINGS ARE BY DEFAULT IN STANDARD MODELS, CHANGES CAN BE MADE AS PER CUSTOMERS REQUIREMENT

- ALL PANEL ARE MARKED WITH AKLOK BRAND NAME, SALES ARE SUBJECTED TO DEALERS ONLY, NO DIRECT SALE TO PLATS AND END USERS

- 1 YEAR MANUFACTURING WARRANY WILL BE PROVIDED FROM THE MANUFACTURING DATE, ANY ALTERATION IN THE SYTEM WILL LEAD TO CANCELATION OF WARRANTY

- FOR ANY ASSISTANCE / TECHNICAL CLEARANCE PLEASE CONTACT US AT +919769700998.

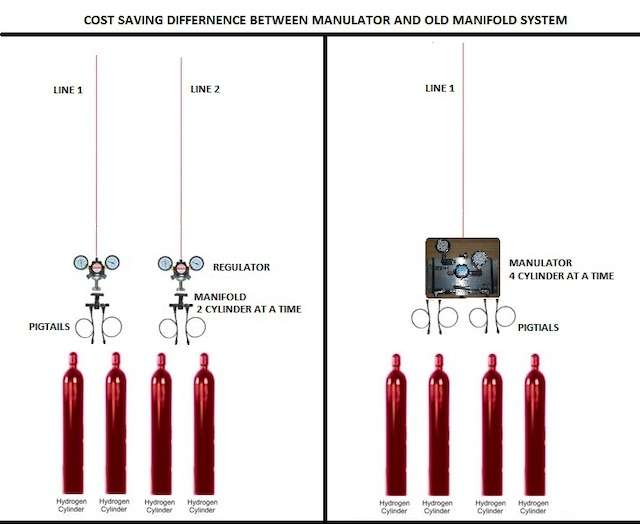

- AS YOU SEE IN THE ABOVE IMAGE WITH OLD MANIFOLD SYSTEM, EACH MANIFOLD CAN HANDLE ONLY 2 CYLINDERS AT A TIME. HENCE IN ORDER TO USE MORE CYLINDERS CUSTOMER HAS TO BUY A NEW SET OF MANIFOLD. HENCE IF YOU USING MORE THAN 2 CYLINDER CUSTOMER HAS TO PAY EXTRA FOR NEW SET. WHERE ELSE 1 MANULATOR CAN HANDLE MORE THAN 2 CYLINDER. CUSTOMER HAS TO PAY FOR 1 AND CAN USE 2,4,6,8, ETC CYLINDER AS PER REQUIREMENT

- IN OLD MANIFOLD THER ARE VARIOUS JOINT ASSEMBLYS SUCH AS ISOLATION VALVES, REGULATORS ETC, WHICH CAUSE LEAKAGE ISSUES FROM THESE JOINTS. WHERE ELSE MANULATOR IS A SINGLE PIECE DESIGNED SYSTEM WITH IN-BUILD REGUALTOR AND FLOW CONTROL VAVLE, HENCE ALL LEAKAGE ISSUES COMES TO AN END WITH THIS NEW PRODUCT

- AS YOU SEE IN THE IMAGE OBOVE WITH OLD MANIFOLD SYSTEM , FOR EVERY 2 CYLINDER THERE IS AN INDIVIDUAL LINE ( LINE1 , LINE 2) WHERE AS MANULATOR HAS ONLY 1 SINGLE LINE ( LINE 1) FOR ALL FOR CYLINDERS. THIS WILL HELP REDUCING THE COST OF EXTRA LINE (TUBING) WHICH IS USED IN OLD MANIFOLD SYSTEM ( LINE 2)

- THE ABOVE MENTIONED POINTS ARE FEW BASIC POINTS THAT WILL HELP THE CUSTOMERS TO UNDERSTAND THE COST SAVING FACTOR BETWEEN THE OLD MANIFOLD SYSTEM AND MANULATOR.

- THERE ARE MUCH MORE BENEFITS OF THIS PRODUCT WHICH A CUSTOMER WILL COME TO UNDERSTAND AFTER USING IT .